What are the advantages of the iMAP Insulation Management System?

Using the iMAP Insulation Management System, auditors can easily document the location of insulation systems using floor plans, detailed descriptions, and geotagged images. The software helps auditors catalogue the type, thickness, and condition of insulation.

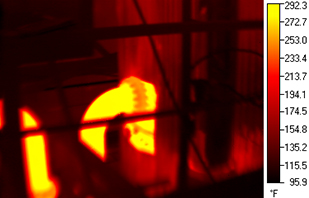

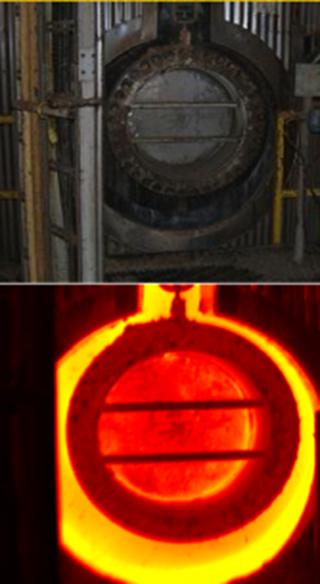

Infrared thermography can help identify corrosion under insulation that can go undetected in a visual inspection. Corrosion can result from steam leaks or intruding water entering systems via capillary action or other sources.

A heat loss calculator, integrated into iMAP Software, calculates current heat loss, heat loss after repairs or upgrades are completed, and energy and cost savings. By including the cost of repairs or upgrades, the software calculates the payback period, so you can maximize your return on investment. Insulation upgrades often have a payback of less than a year. iMAP Software also calculates greenhouse gas emissions before and after upgrades, providing valuable information for facility environmental plans.

iMAP Software prioritizes insulation maintenance and repair projects using priority codes that take into account a facility’s industry, applicable standards, energy efficiency requirements and objectives, corporate maintenance policies, type of damage, and existing condition. Tackling high-priority repairs a facility’s life cycle, optimizes energy efficiency, and increases worker safety.

iMAP Software’s thermal insulation codes are endorsed by the National Insulation Association’s Technical Information Committee for evaluating hot, bare surfaces, existing insulated piping, and existing insulated equipment. iMAP Software ensures a consistent approach to data collection, data entry, and auditing.

An estimator tool, integrated into iMAP Software, calculates the surface area of any equipment or structure needing insulation refurbishment and converts it into convenient measurements for product ordering purposes, reducing overages and helping provide repair cost estimates.

iMAP Software and the iMAP Insulation Management System are ISO 50001-compatible. iMAP insulation audits help facilities develop a thermal insulation efficiency management plan, part of an ISO 50001 energy management plan, and also reviews performance against energy targets.

Once the audit is completed, iMAP Software creates summary and detailed energy and environmental reports that project energy savings and greenhouse gas emission reductions, helping provide a business case for insulation upgrades and repairs.

A drag and drop report builder in iMAP Software lets facility owners, planners, and auditors build reports that give them the information they need, in a format they want. And secure access from any web browser – even mobile devices – means that users have access to insulation, heat loss, and CUI information no matter where they are.